Aluminum has proven important in a variety of industries due to its lightweight nature, strength, and versatility, with the 7050 alloy standing out as a premium alternative. This alloy is known for its longevity and high performance, making it an excellent choice for industries that require both strength and weight efficiency. Aerospace and other high-stress applications typically rely on this alloy due to its exceptional strength and corrosion resistance, which make it excellent for structural components that must withstand extreme circumstances.

Understanding the Properties of 7050 Aluminum

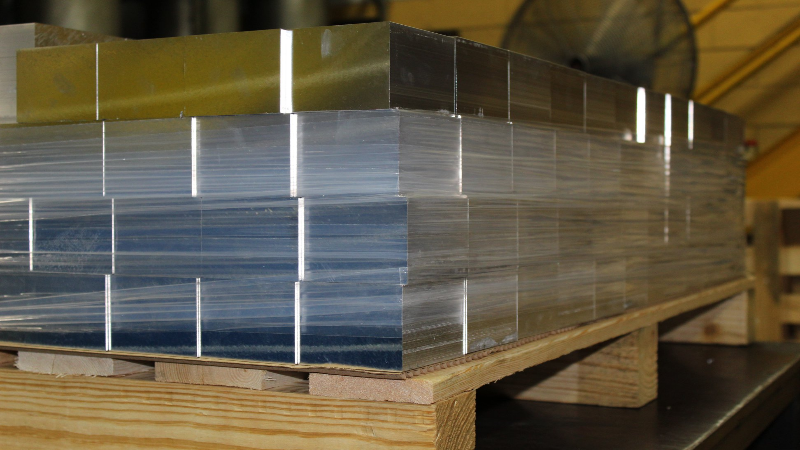

One of the reasons why this aluminum alloy is suited for demanding applications is its exceptional properties. As a high-strength, heat-treated material, it is extremely resilient, especially when compared to other aluminum grades. The alloy’s principal constituents are zinc, copper, and magnesium, which give it outstanding mechanical qualities that withstand high pressure and stress. When paired with the alloy’s other elements, it provides a high resistance to stress corrosion cracking, which is essential in the aerospace, marine, and transportation industries. This alloy’s hardness and outstanding compressive strength, especially at lower weights, have earned it a place among materials suitable for the most demanding applications. The composition of 7050 aluminum allows it to maintain structural integrity even in harsh environmental conditions, leading to its extensive use in areas where safety and performance are crucial.

Applications and Advantages in Aerospace and Beyond

The fundamental advantage of this aluminum alloy is its remarkable resistance to fatigue and fracture, making it perfect for aeronautical components under constant stress. Its durability extends the life of aircraft components, lowering maintenance requirements and total operational expenses. Vital portions of the fuselage, wing skins, and other load-bearing components employ the material, demonstrating its dependability in the high-performance aircraft industry. In transportation, it offers a lighter alternative while maintaining the toughness required for heavy-duty applications. Many high-performance bicycles, for example, use this alloy because it can endure the demands of professional cycling while adding minimal weight. Similarly, car manufacturers use this material in sections that must withstand severe impact and stress, such as chassis and structural reinforcements. Its composition is intended to maximize mechanical qualities while keeping weight low; hence, it is typically preferred over steel in applications where weight is crucial. The alloy’s ability to withstand stress corrosion makes it ideal for marine applications.

Future of High-Performance Alloys Like 7050 Aluminum

As technology advances, so does the demand for high-performance alloys that can withstand extreme temperatures while remaining lightweight. The composition of alloys such as 7050 aluminum continues to vary, with producers adopting novel treatment methods to improve their qualities. The aerospace industry, in particular, is pioneering the use of new alloys to make aircraft lighter, stronger, and more fuel-efficient. In other industries, greater environmental consciousness and a desire for sustainability are driving manufacturers to use materials that lengthen product lifespans. This alloy helps to reduce material waste by lowering the need for regular replacements and maintenance, which aligns with broader sustainability aims. Its unique combination of strength, resistance, and lightweight qualities has made it a vital material in a variety of high-performance industries. Whether used in aircraft, maritime, or transportation, this alloy continues to set standards and demonstrate the potential of modern engineering.